GrinderCrusherScreen Your Source For Asphalt Crushers Since 1973

WHY CHOOSE GRINDERCRUSHERSCREEN?Since 1973, GrinderCrusherScreen and Screen USA have operated out of Smyrna, GA. Here, we house an extensive inventory of new equipment and our industry-leading parts department, with knowledgeable staff and replacement parts for all types of recycling equipment. A brick-and-mortar location allows GrinderCrusherScreen to stock parts stateside, saving our customers time and money by eliminating the lead times associated with ordering parts from overseas, as many of our competitors without brick-and-mortar locations do.

Shop Our Selection of Asphalt Crushers, Shredders, and Conveyors

TURN ASPHALT WASTE INTO PROFIT WITH A MOBILE ASPHALT CRUSHER

Add dollars to your bottom line by recycling asphalt into a usable and resellable aggregate. Recycled asphalt is currently one of the most in-demand products on the market and demand is only expected to increase over time. If your operation wants to increase your asphalt recycling capabilities the GrinderCrusherScreen team has you covered. Since 1973, our experts have helped business owners like yourself source the correct impact crushers and shredders for your asphalt crushing needs.

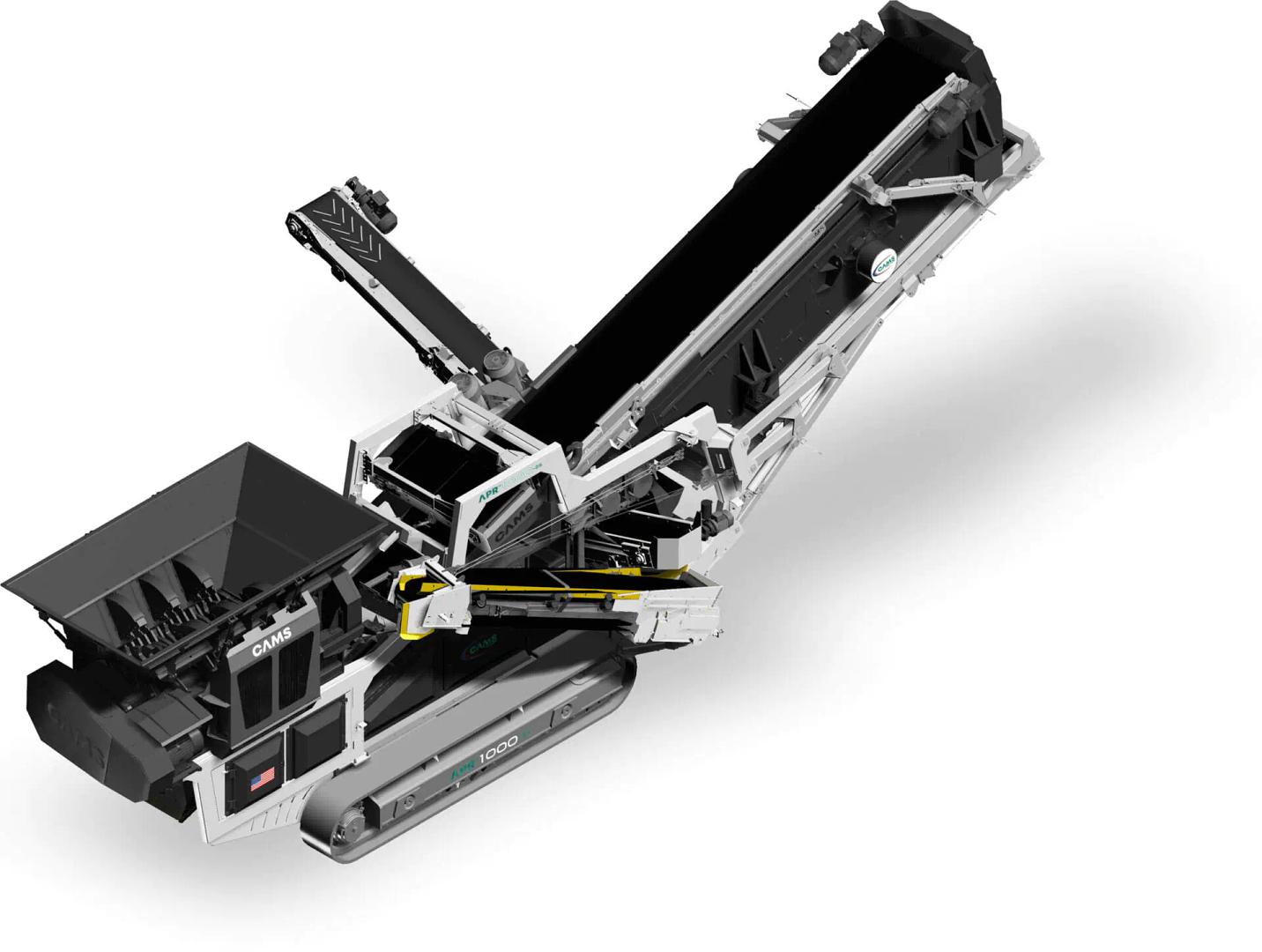

CAMS APR1000-2S Asphalt/RAP Shredder

The APR1000-2S is the combination of 2 shredders, 1 magnetic separator, and 1 screener all in 1 machine. The perfect solution to recycle slabs and milled asphalt.

Link

GCS VSI35 - Impact Crusher

Available in portable or stationary along with various options including multiple rotor and ring choices. The VSI35 also features an adjustable feed tube, a hydraulic lid lifter for quick, easy inspection or maintenance, and interchangeable crushing chambers (along with different rotors and rings) for a broad range of applications. The VSI35 software also allows you to maximize your production by giving you more control, adjustments, and more information.

Options available include:

- Trailer or skid mounting (portable or stationary)

- Conveyors - Dust control systems

- Internal wet kits (for sticky material)

- Oil coolers/heaters

- Generators/Diesel motors

Link

CHECK OUT OUR SELECTION OF NEW & USED EQUIPMENT

Impact crushers: Ideal For Asphalt

The impact crusher is the most common crusher for asphalt, given the soft abrasive nature of asphalt, jaw crushers tend to get gummed up during crushing runs, particularly in warmer climates and temps.

New & Used asphalt shredders for sale

GrinderCrusherScreen recommends shredders for recycling asphalt for a few key reasons. First and foremost, the cost per ton is significantly less than the cost of running an impact crusher of a comparable price point.

Financing Available for new & Used asphalt crushers

GrinderCrusherScreen and our financing partner have worked hand in hand to develop an industry-leading financing program designed specifically to the needs and specifications of our customers. Because of our reputation and longevity in the recycling business, we are able to finance new equipment over 7 years, slightly used equipment over 6 years, and older equipment over 5 years, while providing industry-leading rates. This allows our customers to benefit from lower payments while protecting their cash flow.